Mobile : +91 9488 444777, +91 94868 58777

Landline : +91 9488 444777

Air cooled Heat Exchanger

Heat Transfer Equipments Air Cooled Heat Exchangers are designed and fabricated in accordance with ASME Section VIII, Div. 1.

Air cooled heat Exchangers are same In the Functions of Finned Tube Heat Exchanger. This type of Heat Exchangers are Specially used in Large Quantity cooling Requirements. We are main Suppliers Air cooled Heat Exchanger for Oil Refineries and Process Fluid Cooling.

Types of Air cooled Heat Exchangers by Fan Contact:

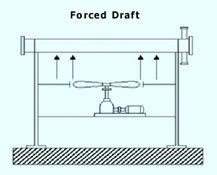

1.Forced Draft Air cooled Heat Exchanger ACHE

The most economical and most common style air cooler, the forced draft ACHE, uses axial fans to force air across the fin tube bundle. The fans are positioned below the bundle thus not exposing the mechanical sections to the hot exhaust airflow. The forced draft air cooler also simplifies future plant expansion by providing direct access to bundle for replacement. Structural disassembly is not required.

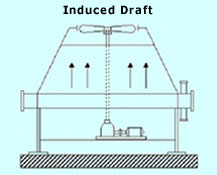

2. Induced Draft Air cooled Heat Exchanger ACHE

The second most economical and most common style air cooler is the induced draft ACHE. This design uses axial fans to pull air across the fin tube bundle. The fans are positioned above the bundle thus offering greater control of the process fluid and bundle protection due to the additional structure. Lower noise levels at grade are another benefit. The induced draft air cooler does require some structural disassembly if bundle replacement is required.

Types of Finned Tubes:

Finned Tubes are most important part of the Heat exchanger which affect the efficiency of the Air Cooled Heat Exchanger. Below mentioned some types of Finned Tubes manufactured by us.

For more Types of Finned Tubes, visit Finned Tube Heat Exchanger page.

"L" Tension FINS

"L" Fins are Tension wound to base Tubes

Maximum working temperature =130 °C/270 °F

Atmospheric corrosion resistance: Acceptable

Mechanical resistance: Poor

"LL" Fins

Overlapped L" Fins are an Economical alternative for Extruded Tubes

Maximum working temperature =165 °C/330 °F

Atmospheric corrosion resistance: Acceptable

Mechanical resistance: Poor

TUBE MATERIALS INCLUDE:

- Carbon Steel, Seamless, and Welded

- Stainless Steels, Seamless, and Welded

- 2205 Duplex

- Copper, Copper Nickel, Admiralty Brass

- Titanium

Types of Air cooled Heat Exchanger Design By Fluid Flow:

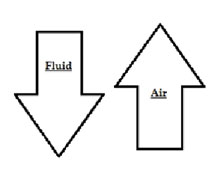

1. Counter-Current Flow Air cooled Heat Exchanger

From Our Supply, This is the most common in the process industry, It cools the hottest fluid with the warmest air, and the coldest fluid with the coldest air. In other words, the process fluid enters the heat exchanger and passes through the finned tubes at the top of the bundle. These top tubes are exposed to air warmed by the lower tube rows. As the process fluid cools and passes through the lower tube rows, the air temperature is lower as it has been exposed to less and less tube rows.

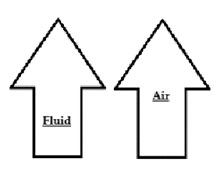

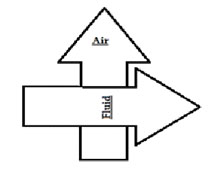

2. Co-Current Flow Air cooled Heat Exchanger

This flow pattern is typically used in processes with critical pour points as it provides the highest outlet process temperature control since it has the lowest efficiency. In this pattern the ambient air cools the hottest fluid, and the hottest air attempts to cool the coldest fluid. The shaded arrows to the right illustrate this flow pattern.

3. Cross - Current Flow Air cooled Heat Exchanger

Most common in the gas compression industry, the cross-current flow pattern exposes each pass of the process fluid to the same air stream. Therefore the pass plates inside the headers are vertical, rather than horizontal, to allow the fluid to pass perpendicular to the air stream.

4. Standards in our finned tube heat Exchangers

Our all air coolers are built to Sect. VIII of the ASME Code, As per pressure vessels Norms. We follow API 661 Standards (Air-Cooled Heat Exchangers for General Refinery Service) For refinery and petrochemical services most customers include. Also, These include such items as galvanizing vs. painting, types of headers, maintenance walkways and platforms, controls, and external loads on the cooler. Also We follows Standardsin Heat Exchanger Constructions.

We are the leading manufacturers of Air Cooled heat exchangers in India. Air cooled heat exchangers offer many unique features, such as: variable-pitch fan hubs, 2-speed motors, galvanized or stainless construction, maintenance walkways, and other special features required for your application.

Header Types For Air Cooled Heat Exchangers

PLUG HEADER

Plug header is the most commonly used up to 160 bar working pressure. The plug holes opposite each tube allows expansion of the tube in the tube sheet, mechanical cleaning and plugging in case of leakage. Seal welding or strength welding can be provided for high partial hydrogen pressure resulting in a less expensive solution than pipe header.

COVER PLATE HEADER

Cover plate is used for fluids with high fouling factors and upto 40 bar maximum when frequent mechanical cleaning is needed. It is also used for very corrosive process fluids so as to periodically check corrosion allowance. Special cover plate headers using welded gaskets are provided for hydrogen service in hydro-cracking plants.

WELDED BONNET HEADER

Welded bonnet type is used in some special services such as Ammonia condensers, Freon condensers and Vacuum Steam condensers. One advantage of this design is the fully welded construction which provides perfect sealing required for such applications.

MANIFOLD HEADER

A large circular manifold is used in some cases where the allowable pressure drop is very low. This large manifold ensures an equal distribution of fluid flow in the tubes. The tube sheets are directly welded to the manifold. This type is used for vacuum steam condensers and refrigeration units

PIPE HEADER

Pipe headers are used for working pressure over 200 bar. The U bend tubes are welded to weldolets on the pipe. The welds are heat treated and X-ray tested.

HEADER MATERIALS INCLUDE:

- Carbon Steel, Normalized

- HIC quality and HIC Tested Carbon Steel

- Stainless Steels

- 2205 Duplex

- Titanium

Air Cooled Heat Exchanger Applications

Petroleum Refining

- Process Coolers / Condensers

- Cooling Tower Fans

- Cooling Water Coolers

- Air Cooler Fans

Oil & Gas Production

- Gas Coolers

- Gas Compressor Inter / After Coolers

- Air Cooler Fans

Power generation

- Cooling Tower Fans

- Steam Condensers

- Seal / Lube Oil Cooler

- Closed-Loop Cooling Water Coolers

- Geothermal Plant Condensers

- Air Cooler Fans

- Turbine lube oil coolers

- Turbine intercoolers

Petrochemical

- Process Coolers

- Cooling Tower Fans

- Steam Condensers

- Air Cooler Fans

Gas Processing

- LNG Plants

- Process Coolers

- Amine Re-boilers

- Air Cooler Fans

- Cooling Tower Fans

Oil & Gas Transport

- Compressor Inter / After Cooler

- Jacket Water Coolers

Pre Heaters

- Air pre-heaters

- Combustion pre-heaters

- Flue gas re-heaters

Hydraulic & Lubrications Systems

- Oil coolers

- Air Cooled Heat Exchangers

Condenser:

- Steam condensers

- Overhead condensers

Refrigeration:

- Refrigerant condenser

- fin fan air cooling systems

Fertilizer:

- Process Coolers

- Solvent Condenser

Water Treatment, Industrial Application

- Water coolers

- engine coolers

Air Cooled Heat Exchangers Manufacturer INDIA

- Home

- Heat Exchanger Manufacturers

- Products

- Contact Us

- Enquiry

- Shell & Tube Heat Exchanger

- U Tube Bundle Heat Exchanger

- Air Cooled Heat Exchanger

- Air Cooled Condenser

- Oil Coolers

- Marine Heat Exchanger

- Kettle Reboiler Type Exchanger

- Double Pipe Heat Exchanger

- Flue Gas Air Preheater

- Plate Finned Heat Exchanger

- Plate Heat Exchanger

- Brazed Plate Heat Exchanger

- Pressure Vessel Manufacturers

- Coil Type Heat Exchanger

- Removable Tube Sheet

- Fixed Tube Sheet

- Tube Bundle Heat Exchanger

- Vertical Shell Tube

- Air Heat Exchanger

- Aluminium Heat Exchanger

- Compact Heat Exchanger

- Copper Heat Exchanger

- Finned Tube Heat Exchanger

- Water Heat Exchanger

- Stainless Steel