Mobile : +91 9488 444777, +91 94868 58777

Landline : +91 9488 444777

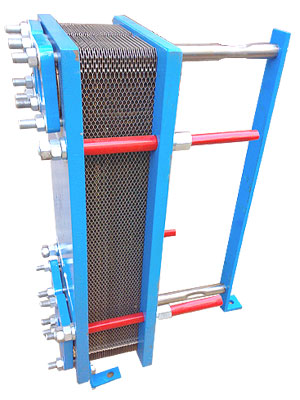

Plate Heat Exchangers Manufacturers INDIA

The difference lies at plate design, sealing technology, capacity range, product range etc. We always continue to improve our Plate heat exchanger to give total customer's satisfaction.

Plate Heat Exchanger Features

- High heat transfer coefficients

- Optimized heat recovery

- Compact constructions

- No mixing of product

- Flexibility to change plate arrangement and to add / remove plate

- Easy maintenance and suitable for CIP, plate pack easily accessible

Plate Heat Exchanger

A plate type heat exchanger is a type of heat exchanger that uses metal plates to transfer heat between two fluids. This has a major advantage over a conventional heat system in that the fluids are exposed to a much larger surface area because the fluids spread out over the plates. This facilitates the transfer of heat, and greatly increases the speed of the temperature change. It is not as common to see plate heat exchangers because they need well-sealed gaskets to prevent the fluids from escaping, although modern manufacturing processes have made them feasible.

The concept behind a plate heat exchanger is the use of pipes or other containment vessels to heat or cool one fluid by transferring heat between it and another fluid. In most cases, the exchanger consists of a coiled pipe containing one fluid that passes through a chamber containing another fluid. The walls of the pipe are usually made of metal, or another substance with a high thermal conductivity, to facilitate the interchange, whereas the outer casing of the larger chamber is made of a plastic or coated with thermal insulation, to discourage heat from escaping from the exchanger. The plate heat system (PHE) s was invented by Dr Richard Seligman in 1923 and revolutionized methods of indirect heating and cooling of fluids.

Plate exchanger one is composed of multiple, thin, slightly-separated plates that have very large surface areas and fluid flow passages for heat transfer. This stacked-plate arrangement can be more effective, in a given space, than the shell and tube heat system. Advances in gasket and brazing technology have made the plate type heat system increasingly practical. In HVAC applications, large exchangers of this type are called plate-and-frame; when used in open loops, these heat system are normally of the gasket type to allow periodic disassembly, cleaning, and inspection. There are many types of permanently-bonded plate heat system, such as dip-brazed and vacuum-brazed plate varieties, and they are often specified for closed-loop applications such as refrigeration.

Plate heat systems also differ in the types of plates that are used, and in the configurations of those plates. Some plates may be stamped with "chevron" or other patterns, where others may have machined fins and/or grooves.

Liquid foods such as milk, fruit juices, beers, wines, and liquid eggs are pasteurized using plate-type. Wine and fruit juices are normally deaerated prior to pasteurization in order to remove oxygen and minimize oxidative deterioration of the products. Plate Type heat exchanger consist of a large number of thin, vertical steel plates that are clamped together in a frame. So it may called as Plate and Frame.

We manufacture Plate Heat Exchanger that are used in dairy, pharma and biotechnology, beverages, brewery, chemical and power sectors. PHE plates are available in MOC AISI 304, AISI 316, AISI 316L, Titanium, Hast alloy, Monel in range thickness from 0.5mm to 0.9mm. It is suitable for handling fluid from 100 LPH to 3.5 Million LPH.

The plate heat exchanger sare available in herring bone, free flow and semi welded construction and depending on application respective plates are selected.

Plate heat exchangers - Bolted design (plate and frame)

Heat transfer plates are characterized by optimum embossing resulting in high heat transfer coefficients. This permits low-cost and optimum adoption to the respective application conditions Our product range includes single-pass and multi-pass plate heat exchangers with heat exchange surface up to 1500 m².

Plate Heat Exchanger Technical data:

- heat exchange surface per plate: 0,04 - 2,50 m²

- max. design pressure: 25 bar

- max. design temperature: 170°C

Plate Heat Exchanger Safety:

Our plates are provided with double gaskets at the inlet and outlet which prevent mixing of the two media. If designed as safety heat exchanger, double plates are provided with a special sealing system.

Plate material:

- standard: stainless steel 1.4301/AISI 304, 1.4401/AISI 316

- optionally: 1.4539, 254 SMO, titanium

Gasket material:

- NBR (nitrile-rubber)

- EPDM (ethylene-propylene-rubber)

- Viton (fluorine-rubber)

- Further materials on request

Special series:

- Safety heat exchangers (FPSS)

- Stainless steel design for food and FDA applications

- Compact double PHE-units including cocks and valves

- Design with welded cassettes (FPG)

Plate Heat Exchanger Manufacturers India

- Home

- Heat Exchanger Manufacturers

- Products

- Contact Us

- Enquiry

- Shell & Tube Heat Exchanger

- U Tube Bundle Heat Exchanger

- Air Cooled Heat Exchanger

- Air Cooled Condenser

- Oil Coolers

- Marine Heat Exchanger

- Kettle Reboiler Type Exchanger

- Double Pipe Heat Exchanger

- Flue Gas Air Preheater

- Plate Finned Heat Exchanger

- Plate Heat Exchanger

- Brazed Plate Heat Exchanger

- Pressure Vessel Manufacturers

- Coil Type Heat Exchanger

- Removable Tube Sheet

- Fixed Tube Sheet

- Tube Bundle Heat Exchanger

- Vertical Shell Tube

- Air Heat Exchanger

- Aluminium Heat Exchanger

- Compact Heat Exchanger

- Copper Heat Exchanger

- Finned Tube Heat Exchanger

- Water Heat Exchanger

- Stainless Steel