Mobile : +91 9488 444777, +91 94868 58777

Landline : +91 9488 444777

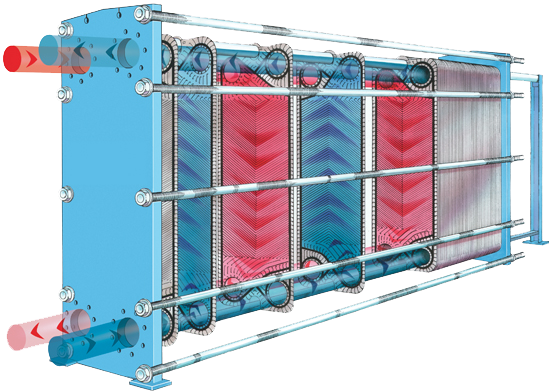

Plate and Frame Heat Exchanger Approach

The Main Factors for Plate and Frame Heat Exchangers are generation from regeneartion and heat retrieving of temperature approach of the higher transfer media. The Particular accuracy of temperatures are of 1°F to 2°F are possible because of the true counterflow and high heat transfer efficiency of the plates. There are very closed temperature approach with 1-2°F (0.5-1.0°C) and Temperature-Crosses (when one fluid is heated or cooled beyond exiting temperature of the other fluid) and then it can be satisfied in a relatively small footstood as it is a true counter flow device with high heat transfer efficiency and migration.

These applications would require more costly, long single-pass Shell & Tube requiring much larger installation footstood of temperature approach. This is an important factor in regeneration and heat recovery processes.As compared to shell and tube , the temperature approach in a plate heat exchangers may be as low as 1 °C whereas shell and tube heat exchangers require an approach of 5 °C or more.The design of the system calls for a close approach temperature to maximize the use of low cost energy. Plate and Frame are the only heat exchangers that can meet these high requirements.

- Home

- Heat Exchanger Manufacturers

- Products

- Contact Us

- Enquiry

- Shell & Tube Heat Exchanger

- U Tube Bundle Heat Exchanger

- Air Cooled Heat Exchanger

- Air Cooled Condenser

- Oil Coolers

- Marine Heat Exchanger

- Kettle Reboiler Type Exchanger

- Double Pipe Heat Exchanger

- Flue Gas Air Preheater

- Plate Finned Heat Exchanger

- Plate Heat Exchanger

- Brazed Plate Heat Exchanger

- Pressure Vessel Manufacturers

- Coil Type Heat Exchanger

- Removable Tube Sheet

- Fixed Tube Sheet

- Tube Bundle Heat Exchanger

- Vertical Shell Tube

- Air Heat Exchanger

- Aluminium Heat Exchanger

- Compact Heat Exchanger

- Copper Heat Exchanger

- Finned Tube Heat Exchanger

- Water Heat Exchanger

- Stainless Steel