Mobile : +91 9488 444777, +91 94868 58777

Landline : +91 9488 444777

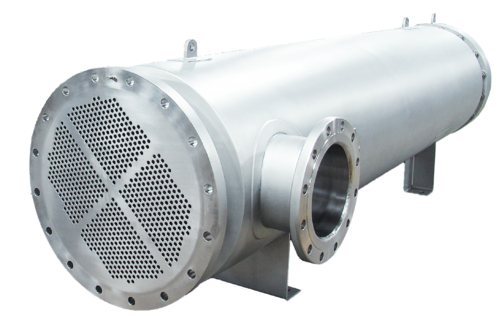

Shell and Tube Heat Exchangers Calculations

The basic design of Shell and Tube calculation for any heat exchanger is the determination of heat transfer area. Overall the shell and tube practice it is more common to assume that fluid properties can be treated as constant at the bulk average values, and approximate the design equations.The Shell and tube Heat Exchanger is a acceptable from the thermal point of view and one may go on to pressure drop calculation.In the calculation of Pressure drop , the pressure drop of each stream must be less than ,but not greatly less than , and the allowable values. If the calculated pressure drop is much less than that allowed, it will probably prove possible to reduce the size of the Heat Systems.The calulation of Shell and Tube Heat systems having calculated methods of tentative sizing , thermal rating, heat transfer co-efficient inside a tube. Shell and Tube Design is a software tool that is made to demonstrate the chemical design & rating calculations of Shell & Tube Heat Exchangers.Unlike other tools, ensures that the calculations are performed step by step to help in understanding the design calculations.

Shell and Tube Heat Exchangers Step by Step Calculations

- Estimate the Physical properties of more than 1450 components

- It has ability to estimate Thermal Conductivity, Density, Heat Capacity and Viscosity. The database also included critical

properties, boiling and melting points. - Estimate mixture properties.

- Integrated customised database functions to allow user to add/delete compnents.

- Ability to import properties to Shell/Tube sides form Microsoft Excel

- Export Results summary to Microsoft Excel

- Ability to calculate unknown shell or tube side temperatures by iteration method (solving by trial and error)

- Also can select from different correlations to calculate shell or tube heat transfer coefficient

- Calculate the scale resistance.

- Shell/Tube side Reynolds and Nusselt numbers

- Buffle spacing.

- Recommended minimun shell thickness, minimum recommended number and diameter of rods.

- Duty Calculation

- Overall heat transfer coefficient

- Shell/Tube velocities.

- Save/Load results.

- Home

- Heat Exchanger Manufacturers

- Products

- Contact Us

- Enquiry

- Shell & Tube Heat Exchanger

- U Tube Bundle Heat Exchanger

- Air Cooled Heat Exchanger

- Air Cooled Condenser

- Oil Coolers

- Marine Heat Exchanger

- Kettle Reboiler Type Exchanger

- Double Pipe Heat Exchanger

- Flue Gas Air Preheater

- Plate Finned Heat Exchanger

- Plate Heat Exchanger

- Brazed Plate Heat Exchanger

- Pressure Vessel Manufacturers

- Coil Type Heat Exchanger

- Removable Tube Sheet

- Fixed Tube Sheet

- Tube Bundle Heat Exchanger

- Vertical Shell Tube

- Air Heat Exchanger

- Aluminium Heat Exchanger

- Compact Heat Exchanger

- Copper Heat Exchanger

- Finned Tube Heat Exchanger

- Water Heat Exchanger

- Stainless Steel